How It Works: PRODEXIS MES & ERP

Setup: Business Flow, Resources & Integrations

To get started with PRODEXIS MES & ERP your business (manufacturing) process flow needs to be set up. The setup is done through the administrative module and it is completely interactive. Each business process flow consists of a certain number of action steps to be executed. Those action steps are organized in workcenters. On the other hand the resources are bound to the workcenters, so the next step of the setup is adding the resources of each workcenter - machines and workers.

The next step of the setup is to add all custom properties of the objects, so that they will comply with your business needs.

Then comes the setup of generatable documents (offers, work orders, handover records, etc...), that consist of creation and uploading of html template files. This part of the setup is the only that requires some html programming skills and if you don’t have a person to do that job, our professionals can do it based on your requirements.

The last step of the setup is to set up integrations with your existing tools and external systems in case such are needed.

Note: Normally the complete setup of PRODEXIS MES & ERP to comply with most of the businesses takes less than a week and no special skills are needed (except development of html templates mentioned above).

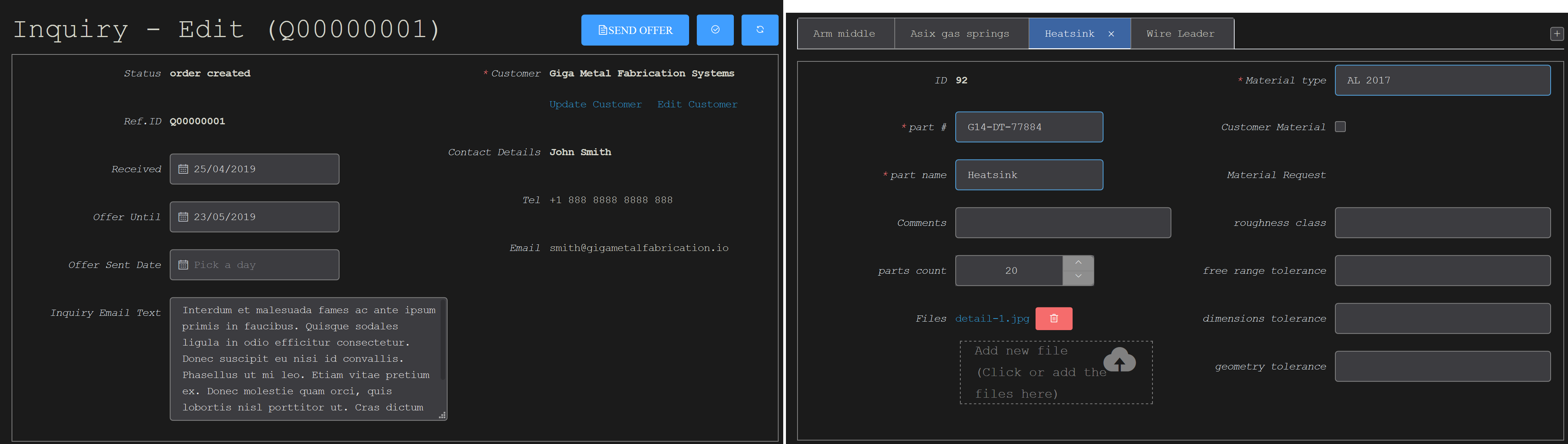

Inquiries, Pricing & Offers

PRODEXIS MES & ERP inquiries management allows tracking of all received inquiries, generation and emailing of the corresponding offers.

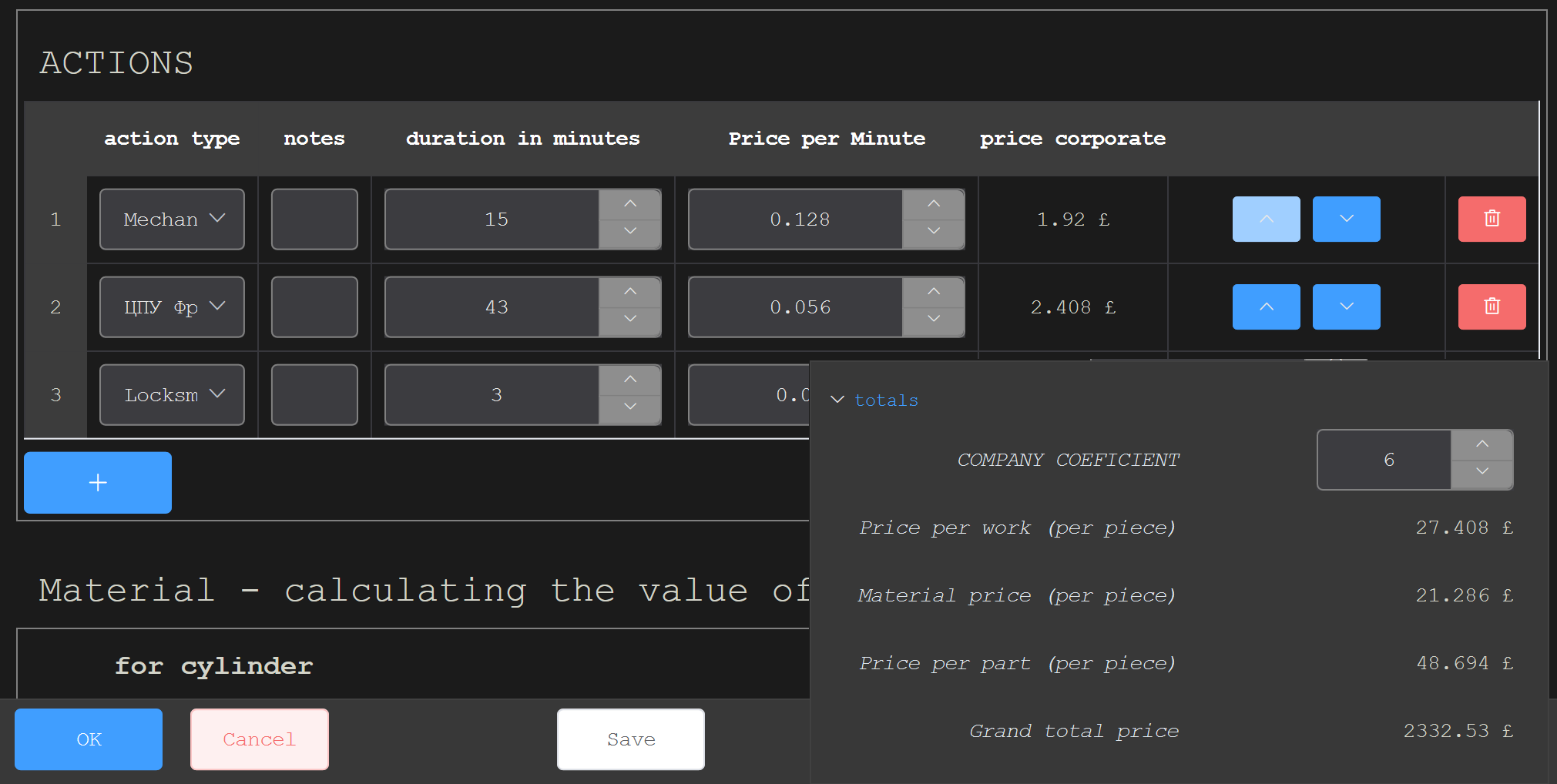

The precise price calculator does real-time calculation of the price to be offered based on the needed raw materials, labor hours and flexible proffit coefficient depending on the order and the customer.

When your customer accepts an offer the production order is generated automatically from the inquiry from which the accepted offer is generated.

Production Order Management & Execution

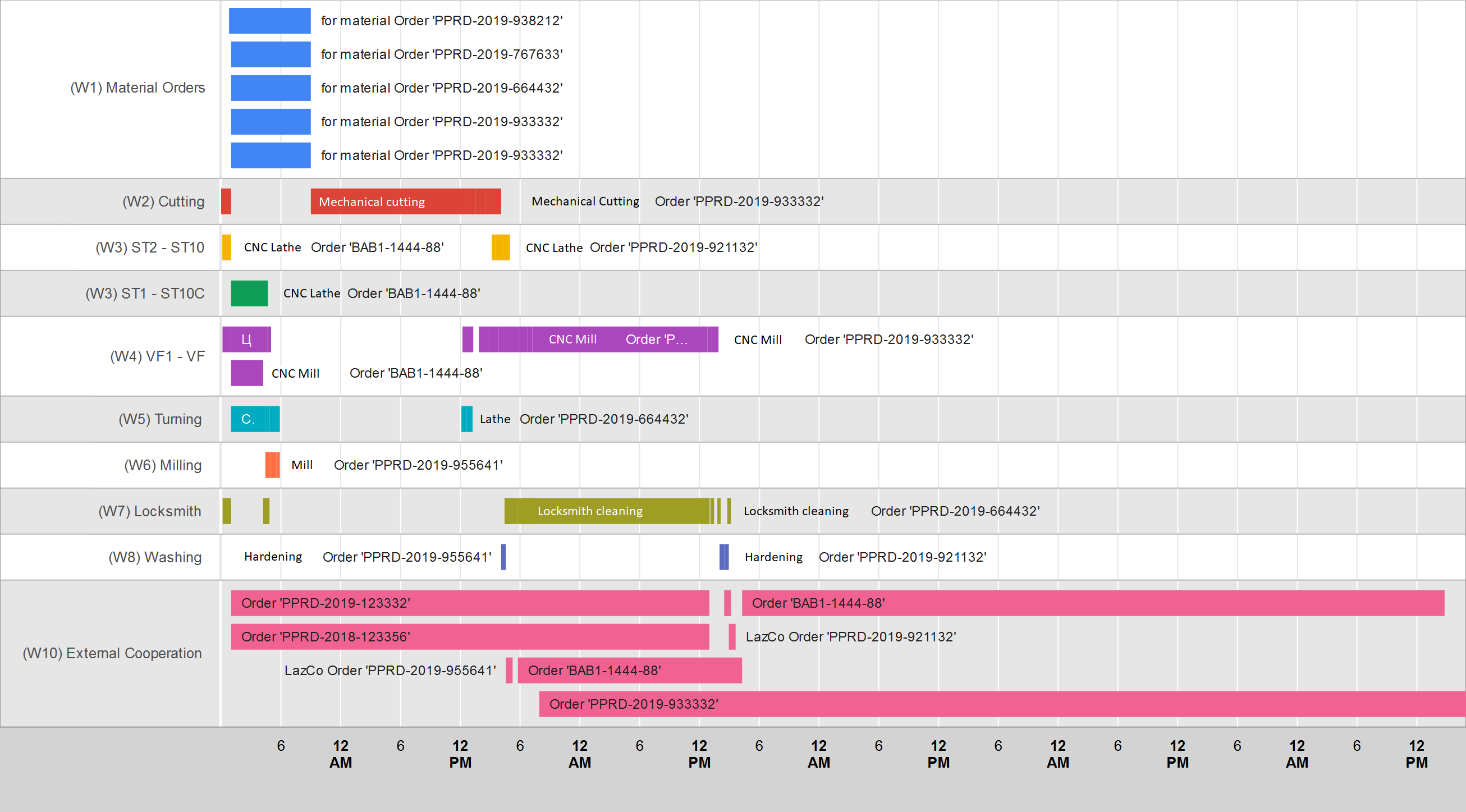

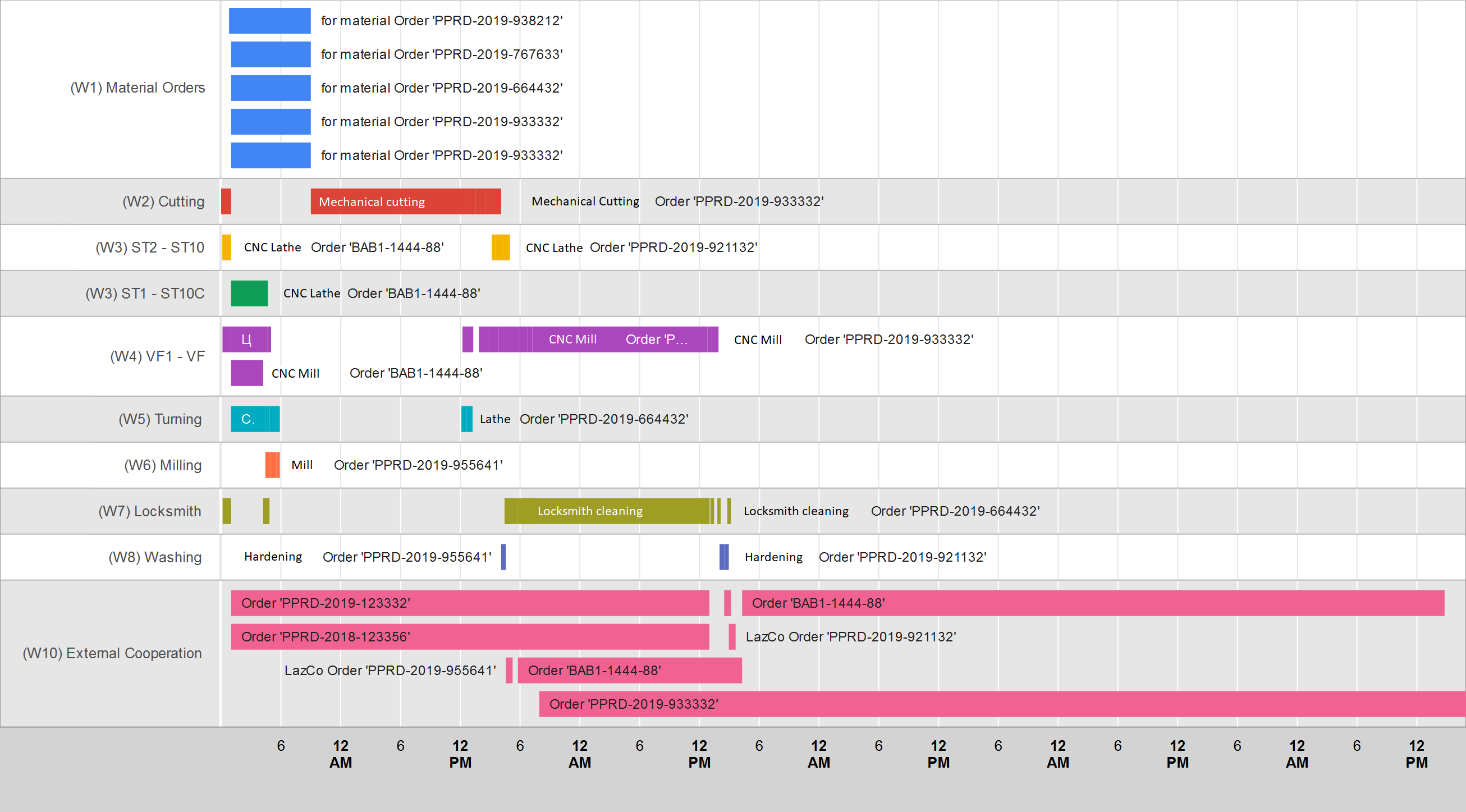

Once production order is created all of its fulfillment action steps are added to the execution schedule according to the specified priority.

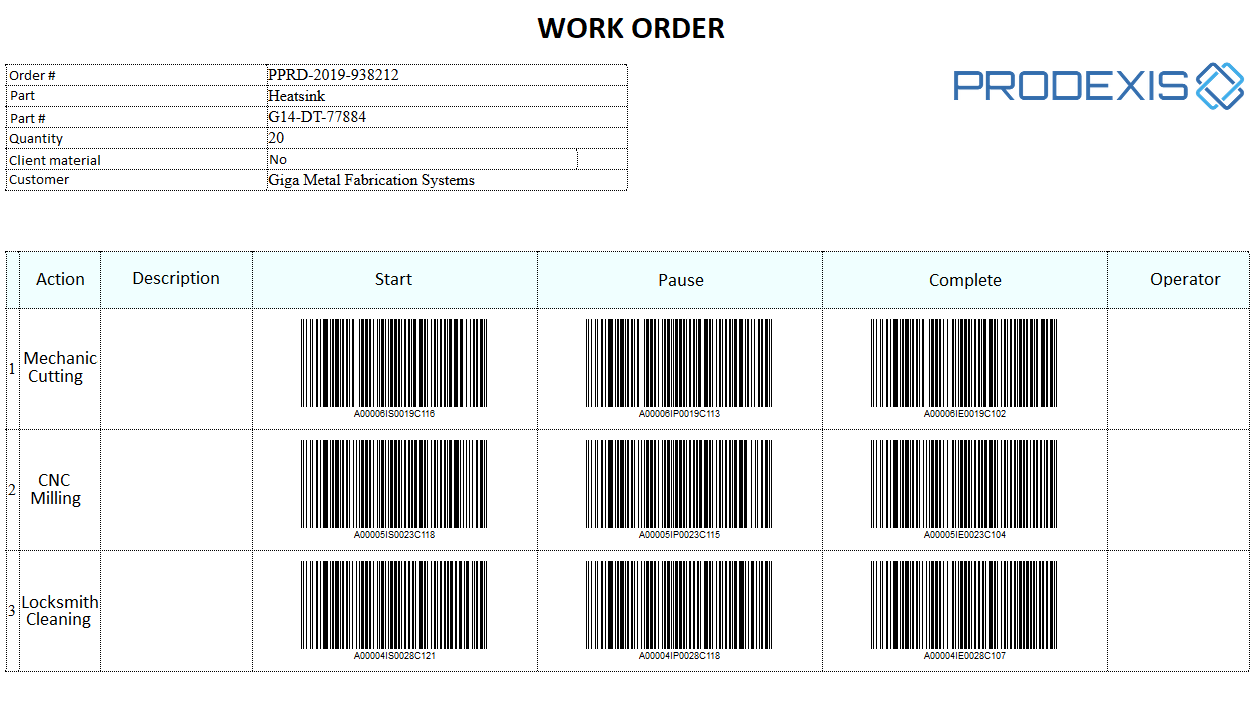

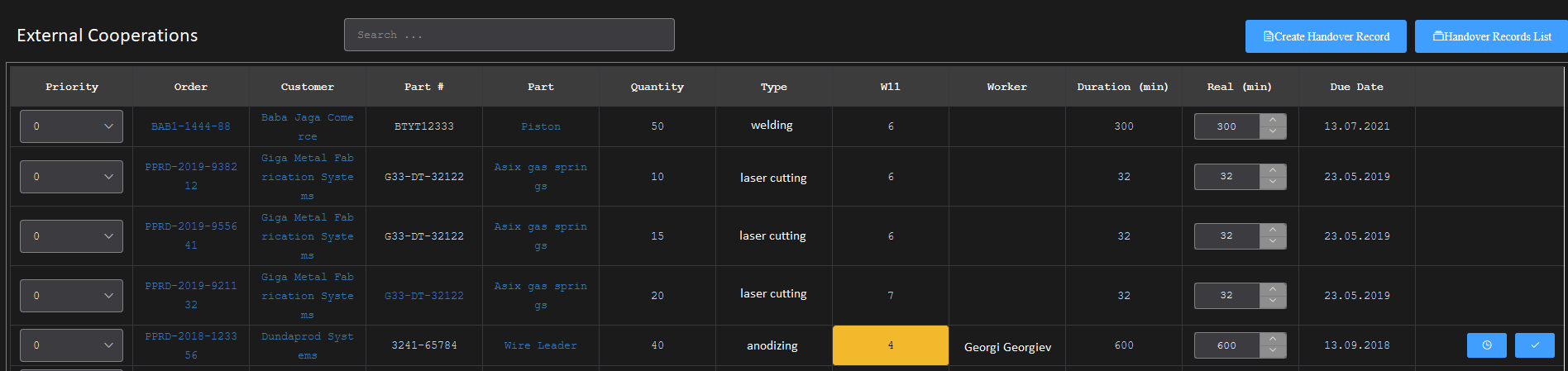

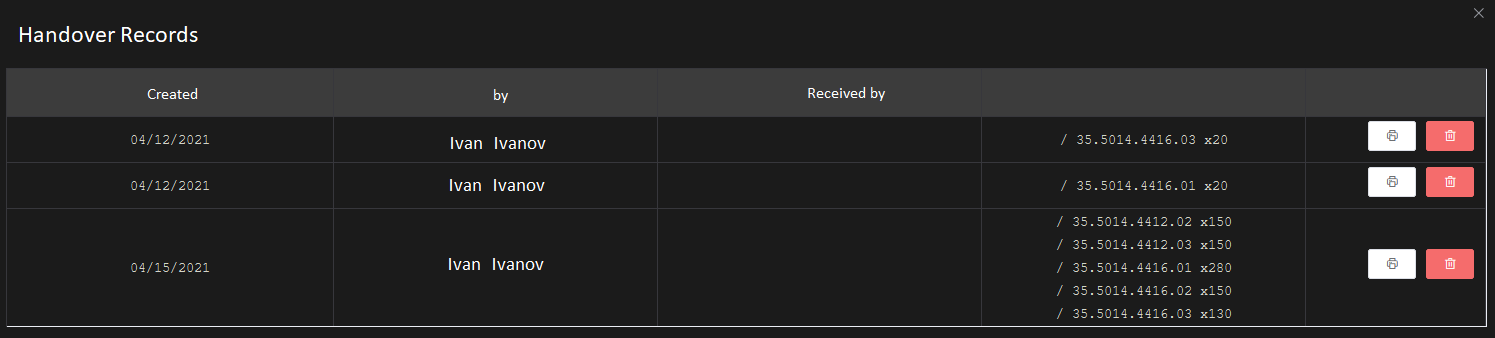

Each of the order items contains complete information on how to fabricate it and deliver it, including drawings, execution steps, material properties, etc. Having this data PRODEXIS MES & ERP generates material orders, work orders and handover records for external cooperations and deliveries.

Manufacturing of each part of the order follows the predefined production flow from material provisioning, fabrication, quality control, billing and delivery to customer.

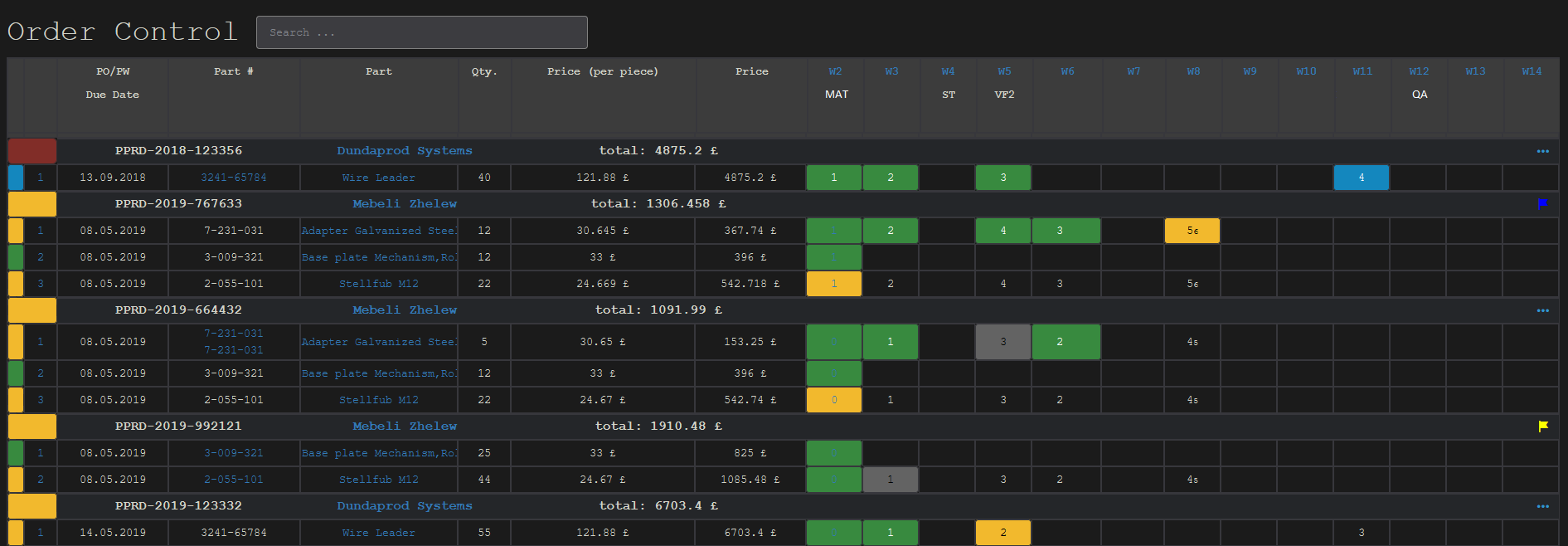

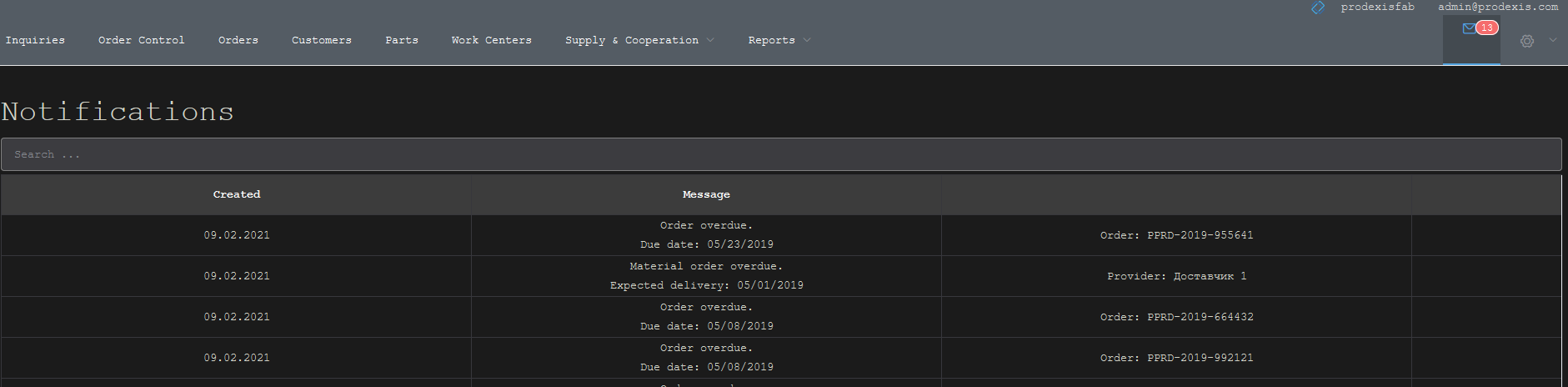

With visualized the essential information about all of the in-process orders PRODEXIS MES & ERP Order Control module gives full picture of the operations. It clearly shows the state of each order, alerts for possible delays and gives real time notification for changes.

The progress of each execution step of the production is managed by a shop flow operator, manager or it is automated via external integrations.

Shop Floor Control provides a clear UI to the operators that can be used with barcode scanner and / or mouse and keyboard. With Shop Floor Control workers are able to start, pause and complete the tasks as well as to obtain drawings and other details of the manufactured products.

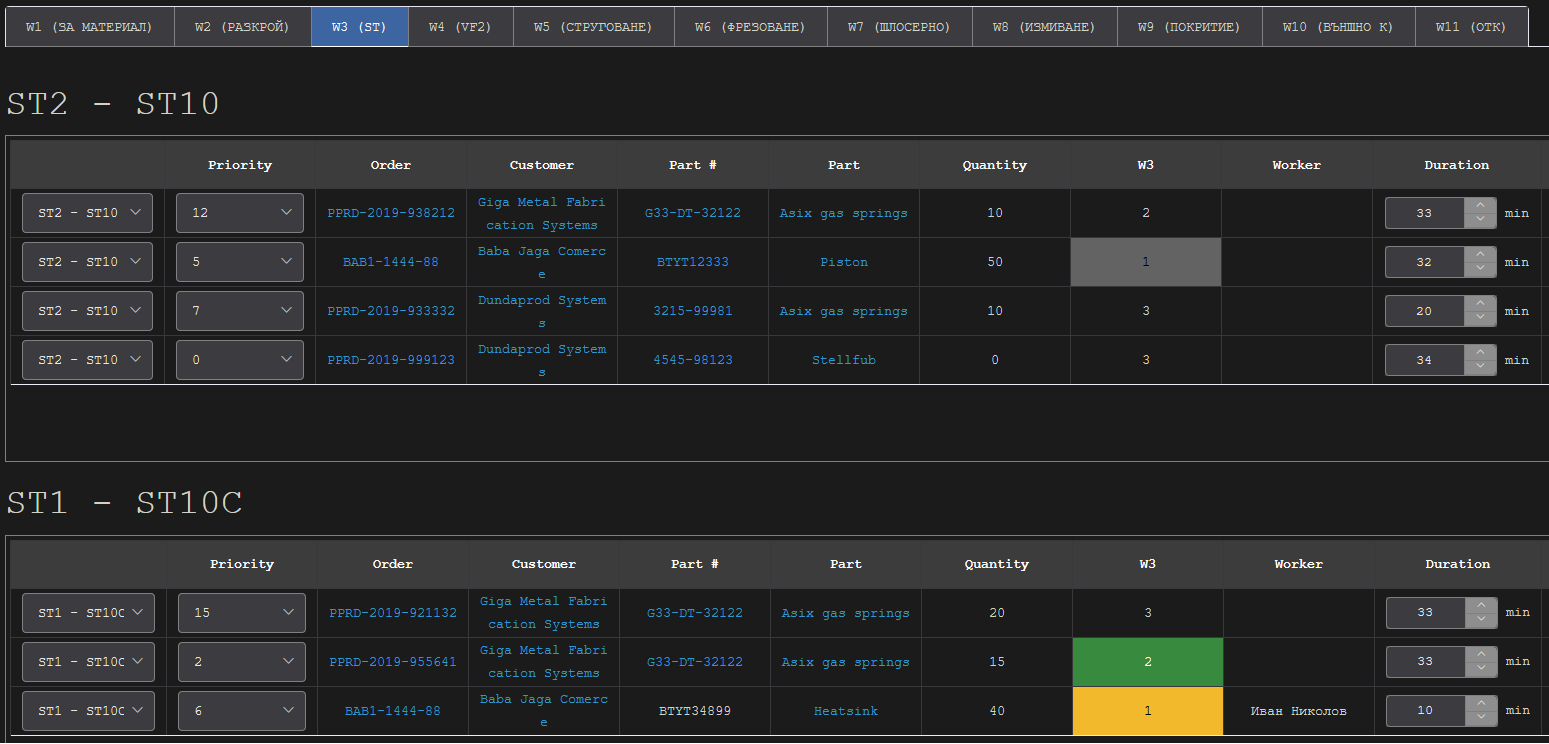

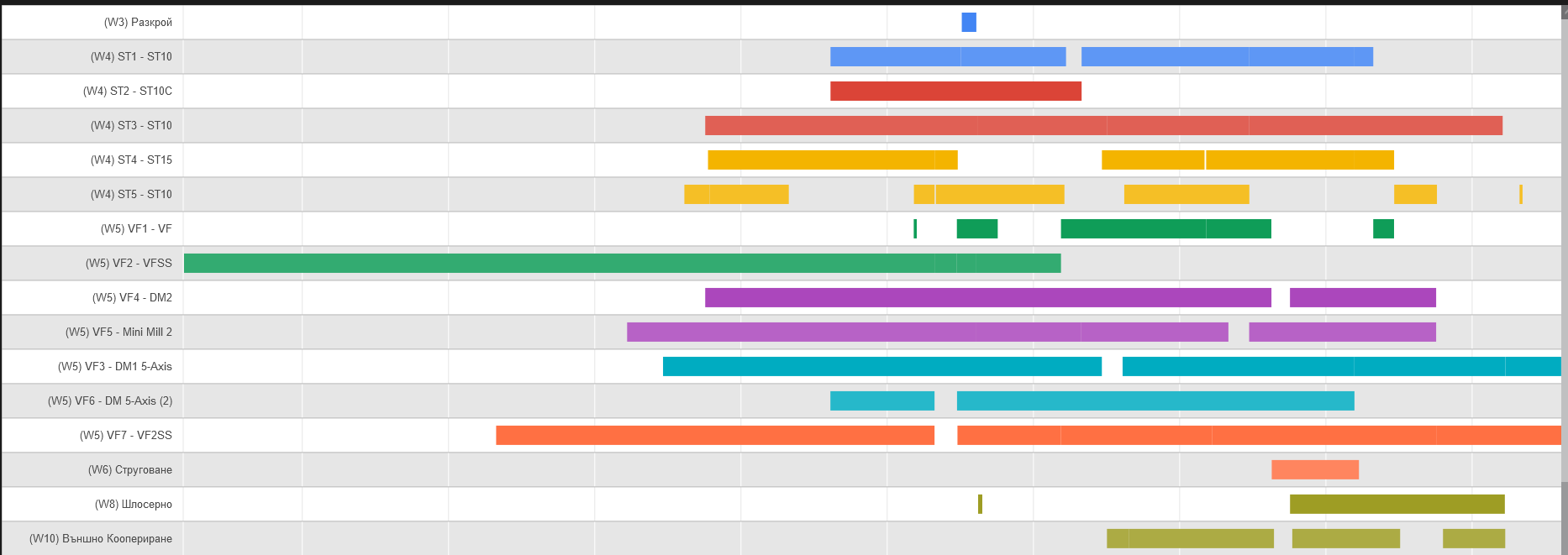

Worcenters module is dedicated to management staff who can monitor, manage and tune the process, by changing the priorities and dealing with tasks and their statuses.

During the manufacturing process if PRODEXIS MES & ERP sees potential delay in the agreed delivery timelines an early report alert is shown, so that corrective actions can be applied to prevent the potential delays.

The lifecycle of each part of each order ends with quality control, delivery and invoicing.

Client Notifications

PRODEXIS MES & ERP allows customers to track their orders via a link without the need to log in, this is done through e-mail notifications and a link to a page containing information about the status of orders.

BI, Costs & Process Optimization

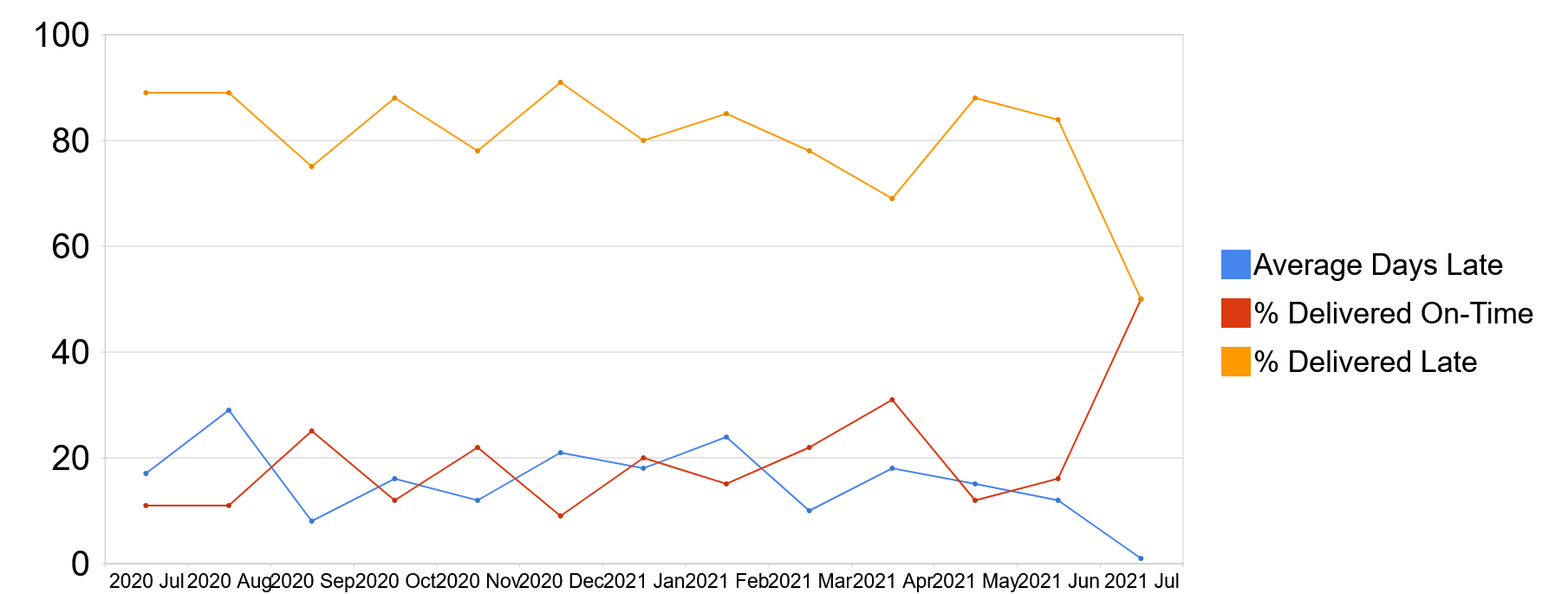

Having a wide range of reports PRODEXIS MES & ERP gives precise business insights based on completed and ongoing manufacturing orders. Those insights allow optimization of the internal processes, optimization of the resources and better planning of material provisioning, external corporations and deliveries.

Execution Schedule

Load history

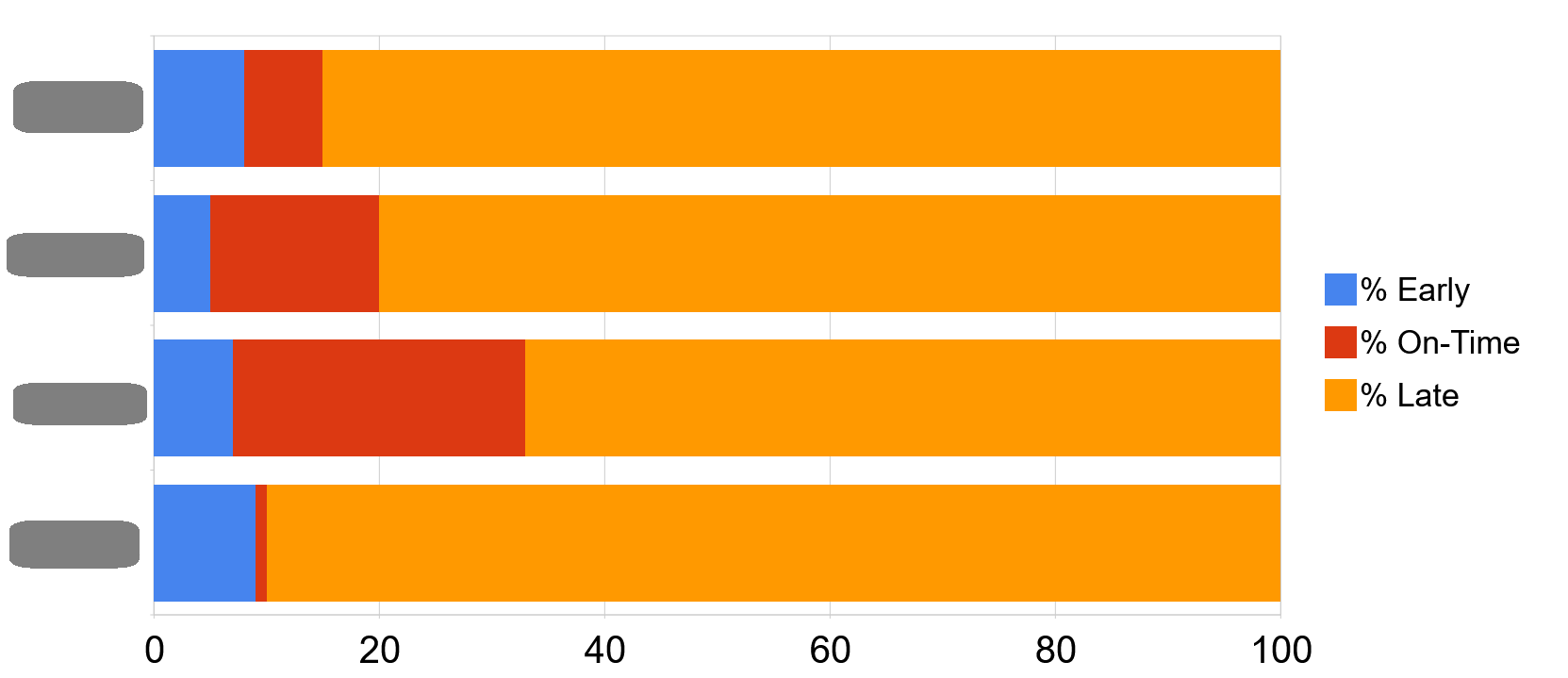

Delivery performance

Cooperator performance

Persistence & Reusability

Every object (inquiry, order, part, customer ...) is stored permanently in PRODEXIS MES & ERP Database, so that it can be reused and managed on demand.

In many cases companies receive same or similar repetitive orders or repetitive products to be fabricated. PRODEXIS MES & ERP facilitates reuse of the persisted historical orders and products to simplify the creation of repetitive ones.